Product Description

WT-1325 model Fiber Laser Cutting Machine with full protection cover, laser source from 3000W to 8000W

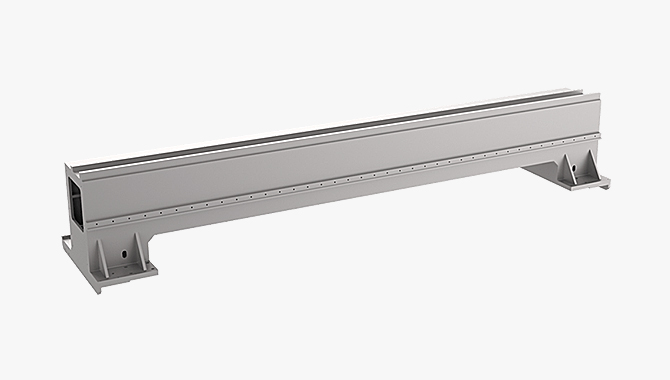

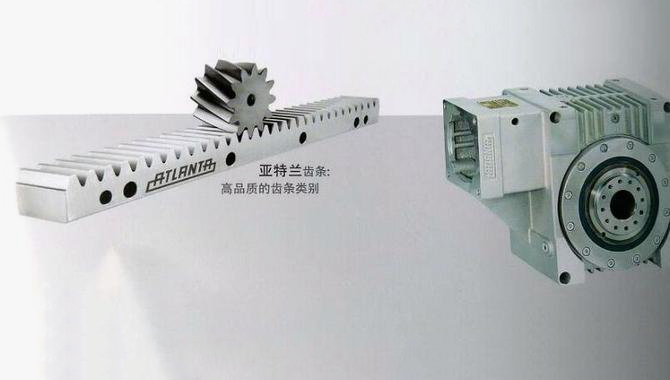

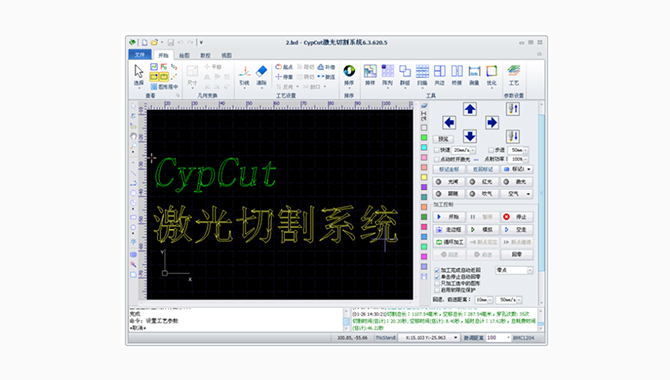

This machine the cutting of sheet metal with high efficiency and high precision, cast aluminum beam finite element analysis is carryout, using lightweight structure design. The perfect combination of NC system ,servo motor run the machine and cutting head make machine running more smoothly, and high repeat positioning accuracy.

Product Applications

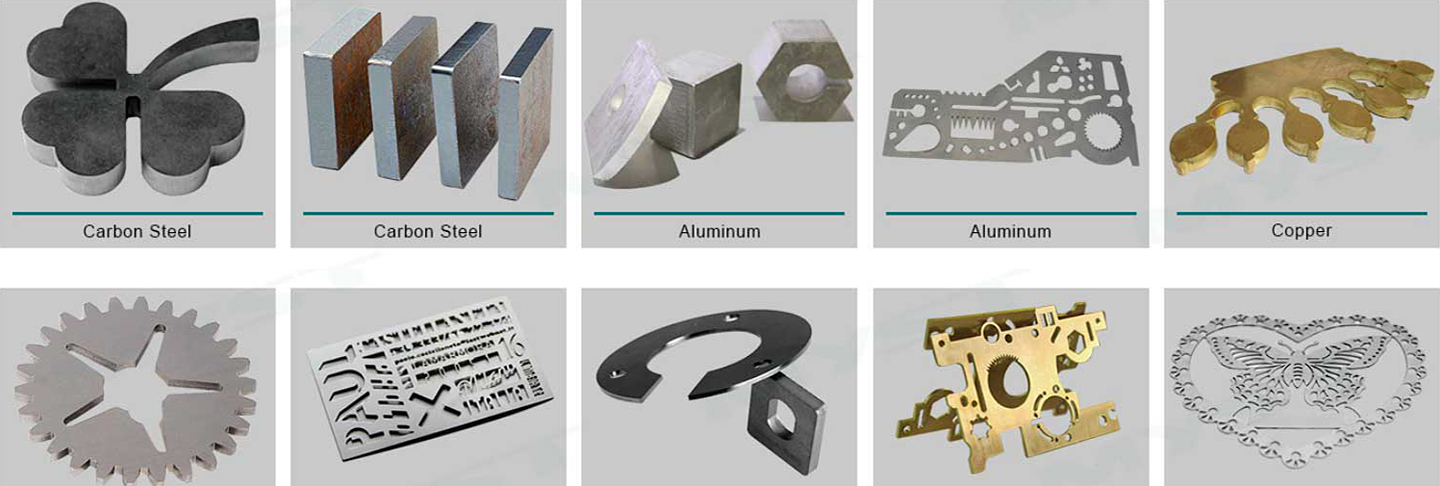

Wise-Cut fiber laser cutting machine is widely used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, food machinery, textile machinery, engineering machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising , Metal processing, kitchenware processing and other manufacturing and processing industries. Cutting materials are in the range stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, aluminized zinc sheet, pickling sheet, copper, silver, gold, titanium and other metal plates and steel pipes.